- ⌂

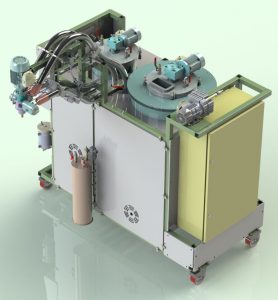

- Dosing systems for high temperature systems

EQUIPMENT

Description

Dosing units of the RG_D series are designed for the processing of polyurethane elastomers based on TDI, MDI. The units are equipped with a wide range of options, which allows you to work with almost all types of hot curing polyurethanes.

Dosing units of the RG_D series are designed for the processing of polyurethane elastomers based on TDI, MDI. The units are equipped with a wide range of options, which allows you to work with almost all types of hot curing polyurethanes.

Plants of the RG_D series are used for the production of wear-resistant products, such as

rollers, screens, screens, bushings, etc., working in many industries.

Equipment

Mobile version - all nodes are located on a mobile frame;

Material of tanks for components - stainless steel;

Dehumidifiers (coalescent filters);

Outlet mechanical cleaning filters;

Level sensors;

pressure sensors;

Electrically heated hoses;

Electrical heating of dosing pumps;

Electric heating of tanks;

Electric heating of the mixing unit;

Component degassing system;

Mixing devices for tanks;

Pigment (dye) dosing unit.

Dosing nodes:

- gear pumps with variable frequency drive.

Specifications

Processable materials:

- polyurethanes (TDI, MDI);

- epoxy resins.

The mixing type is dynamic.

Mixing ratio range: 1:1 to 20:1;

Productivity - from 0,1l/min to 15l/min;

Permissible viscosity limit of the product: up to 350,000 cP;

Component recycling;

Volume of tanks (unified series):

- components A and B (15l, 30l, 50l, 100l, 200l.);

- washing composition (3l, 10l.);

- pigment (0.9l, 1.2l, 1.9l, 5l.).

Characteristics of the temperature control system:

- type of heaters - electric;

- management - multi-zone;

- temperature range - up to +120°С;

- deviation from the set temperature ±2 °С;

- heating temperature control step 1 °C.

Control system:

The control system based on the Segnetics industrial controller performs programming and control of all functions of the plant's electronic systems.

4.3" color touch screen.

Ensures system safety when the critical values of the main operating parameters (temperature, pressure, time, component level) of the installation are exceeded;

The main functions of the control system:

- input and storage of machine operation parameters;

- adjustment of the ratio of components, plant performance;

- mixing head speed adjustment;

- self-diagnosis and emergency automatic shutdown;

- ensuring the operation of the equipment in the "Manual control", "Automatic dosing" mode;

- display of service messages.

Options:

- Automatic tank filling system from external tanks;

- Flowmeters for main components.

[ngg src="galleries" ids="3" display="basic_thumbnail" thumbnail_crop="0"]

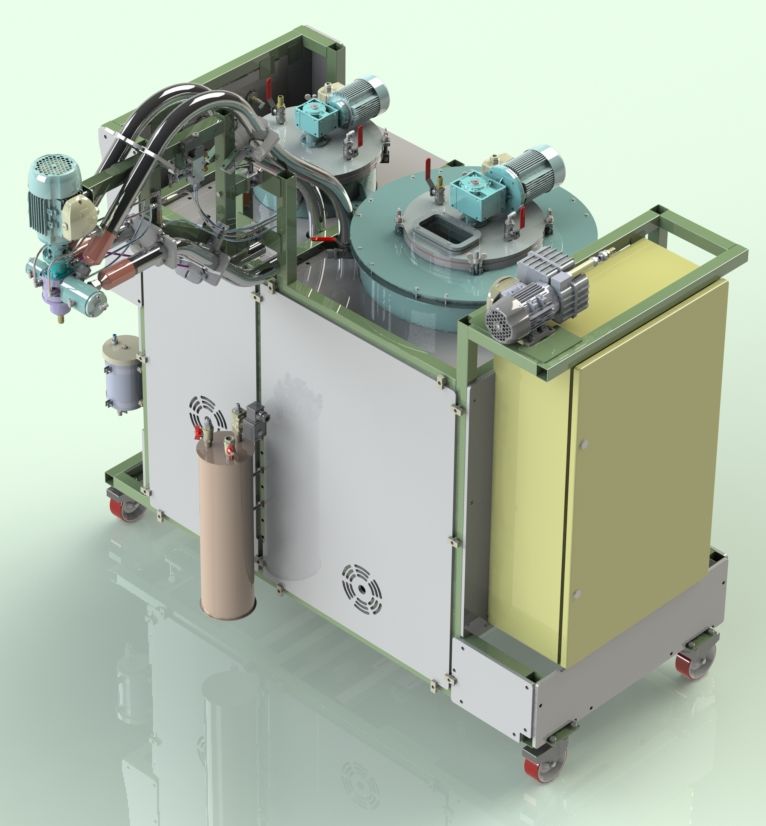

Description

Dosing units of the RG_D series are designed for the processing of polyurethane elastomers based on TDI, MDI. The units are equipped with a wide range of options, which allows you to work with almost all types of hot curing polyurethanes.

Plants of the RG_D series are used for the production of wear-resistant products, such as

rollers, screens, screens, bushings, etc., working in many industries.

Equipment

Mobile version - all nodes are located on a mobile frame;

Material of tanks for components - stainless steel;

Dehumidifiers (coalescent filters);

Outlet mechanical cleaning filters;

Level sensors;

pressure sensors;

Electrically heated hoses;

Electrical heating of dosing pumps;

Electric heating of tanks;

Electric heating of the mixing unit;

Component degassing system;

Mixing devices for tanks;

Pigment (dye) dosing unit.

Dosing nodes:

- gear pumps with variable frequency drive.

Specifications

Processable materials:

- polyurethanes (TDI, MDI);

- epoxy resins.

The mixing type is dynamic.

Mixing ratio range: 1:1 to 20:1;

Productivity - from 0,1l/min to 15l/min;

Permissible viscosity limit of the product: up to 350,000 cP;

Component recycling;

Volume of tanks (unified series):

- components A and B (15l, 30l, 50l, 100l, 200l.);

- washing composition (3l, 10l.);

- pigment (0.9l, 1.2l, 1.9l, 5l.).

Characteristics of the temperature control system:

- type of heaters - electric;

- management - multi-zone;

- temperature range - up to +120°С;

- deviation from the set temperature ±2 °С;

- heating temperature control step 1 °C.

Control system:

The control system based on the Segnetics industrial controller performs programming and control of all functions of the plant's electronic systems.

4.3" color touch screen.

Ensures system safety when the critical values of the main operating parameters (temperature, pressure, time, component level) of the installation are exceeded;

The main functions of the control system:

- input and storage of machine operation parameters;

- adjustment of the ratio of components, plant performance;

- mixing head speed adjustment;

- self-diagnosis and emergency automatic shutdown;

- ensuring the operation of the equipment in the "Manual control", "Automatic dosing" mode;

- display of service messages.

Options:

- Automatic tank filling system from external tanks;

- Flowmeters for main components.

[ngg src="galleries" ids="1" display="basic_thumbnail"]